In 2015‑2019, the Global Alliance for Improved Nutrition (GAIN) convened public and private sector players through the Post‑Harvest Loss Alliance for Nutrition (PLAN) to reduce loss of nutritious foods along supply chains in three countries.

Access the downloadable version of this case study and the complete compendium.

Key Messages

- Currently, vegetable consumption is below recommended levels in 88% of countries and contributes to malnutrition

- In lower‑middle‑income countries (LMICs), a considerable amount of food loss occurs after harvest before it reaches retailers contributing to a reduced supply of these foods in the market

- One way to increase the availability and accessibility of nutritious foods is to focus on reducing Post‑Harvest Loss (PHL) of locally‑produced fruits and vegetables

- 230 supply chain actors joined PLAN Nigeria (N‑PLAN) to explore cold chain options to reduce the loss of the country's vitamin A‑rich tomatoes

- PLAN Indonesia brought together stakeholders along the fish value chain to co‑develop innovative solutions and share insights to reduce postharvest loss and make nutritious, fresh fish more available and affordable

- PLAN Ethiopia worked with the local agricultural university to create a specialized PHL training curriculum, which was then used to conduct training on improved postharvest technologies and business management for 165 supply chain businesses and 26 respective government employees

Introduction

Poor diets are a leading contributor to the non‑communicable disease burden worldwide. Currently, vegetable intake is below recommended levels in 88% of countries, and national vegetable production needs to be increased to meet demand in 61% of countries globally [1]. In lower‑middle‑income countries (LMICs), a considerable amount of food loss occurs after harvest and before it reaches retailers. In Nigeria, 40–50% of fresh fruits and vegetables are 2 lost during crating, transportation, storage, and processing. [2]

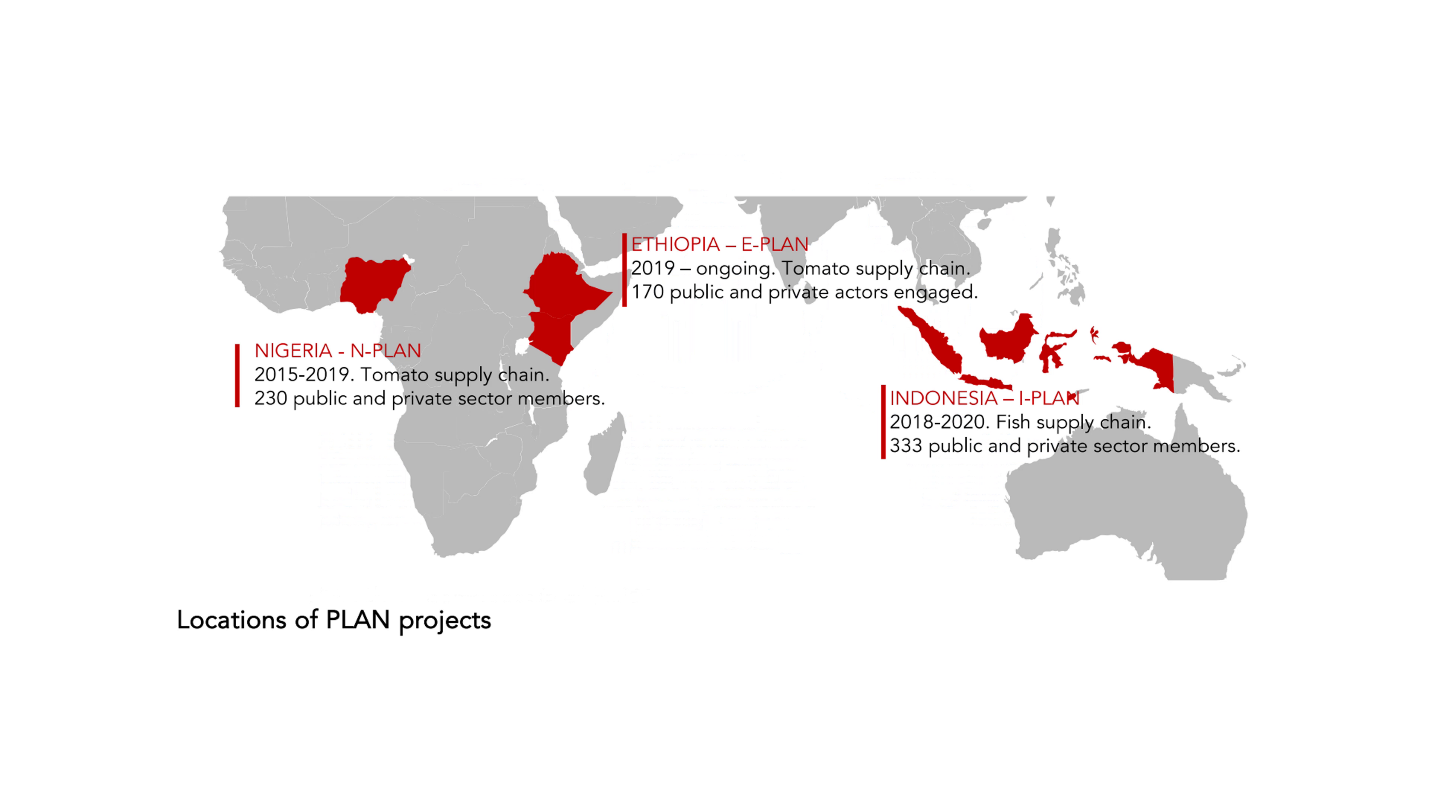

Against this backdrop, the Global Alliance for Improved Nutrition (GAIN), with assistance from USAID, launched the Post‑harvest Loss Alliance for Nutrition (PLAN) in 2015. Over five years (2015‑2019), the project worked with key stakeholders, particularly small and medium enterprises (SMEs), around a specific nutritious food in Nigeria (tomatoes), Indonesia (fish) and Ethiopia (tomatoes) to address the systemic challenges that contributed to high levels of PHL.

Photo caption: PLAN Locations

Convening public and private sector actors to reduce food loss.

PLAN linked public and private sector actors to reduce the loss of nutritious foods, boosting suppliers' livelihoods while increasing the availability and affordability of nutritious and safe foods for consumers.

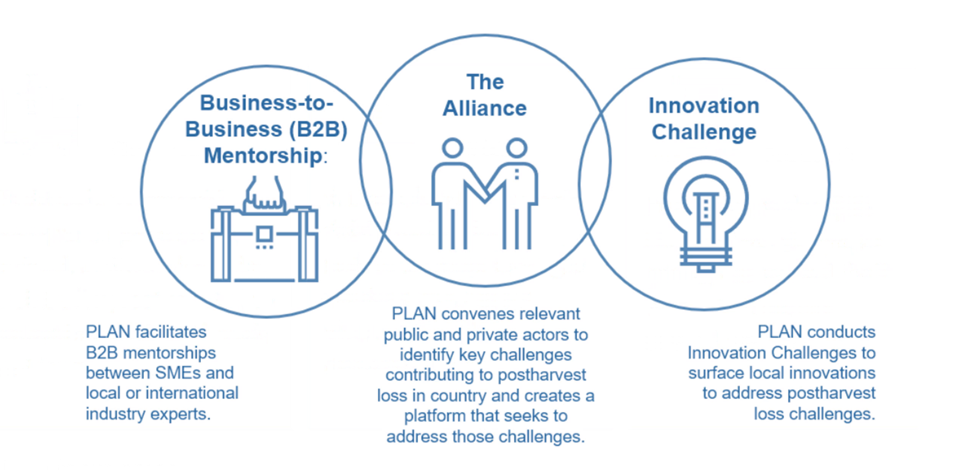

The three‑point PLAN model prioritised Business‑to‑Business mentorships between SMEs, convening relevant public and private actors to identify key challenges through The Alliance and conducting Innovation Challenges to address postharvest loss.[3]

Photo: PLAN's three-point plan.

PLAN linked different actors from across a given supply chain to jointly identify and address the causes of PHL, focusing on the availability of highly nutritious foods. "These SMEs saw a business opportunity to work together, to make improvements to their businesses, and do something good for their country,” said Teale Yalch, EatSafe Project Manager, Operations and Partnerships, at GAIN.

A PLAN for Nigeria

Tomatoes are an excellent source of essential nutrients, such as Vitamins A and C. Nigeria, Africa's most populous country, is the largest producer of tomatoes in Africa, with an annual yield of nearly 2 million metric tonnes.

N-PLAN confirmed that most SMEs were responsible for tomato production and distribution. The long transportation journey from northern Nigeria, where tomatoes are grown, to the large urban markets in the south resulted in a 40-60% loss of their produce. These SMEs needed more opportunity and capacity to adopt new technologies, such as cold chains, to help preserve tomatoes along the supply chain.

To address this challenge, N-PLAN convened small businesses to discuss and co-develop innovative cold chain solutions. Over 200 supply chain actors joined N-PLAN's cold chain alliance to explore refrigeration options and reduce losses of N‑PLAN confirmed that most SMEs were responsible for tomato production and distribution. The long transportation journey from northern Nigeria, where tomatoes are grown, to the large urban markets in the south resulted in a 40‑60% loss of their produce. These SMEs needed more opportunity and capacity to adopt new technologies, such as cold chains, to help preserve tomatoes along the supply chain.

To address this challenge, N‑PLAN convened small businesses to discuss and co‑develop innovative cold chain solutions. Over 200 supply chain actors joined N‑PLAN's cold chain alliance to explore refrigeration options and reduce losses of tomatoes.

A key outcome of the N‑PLAN was the creation of The Organization for Technology Advancement of Cold Chain in West Africa (OTACCWA), a privately led and funded business association focused on developing the cold chain in West Africa. [4] OTACCWA has close to 200 private members and became an affiliate partner of GCCA in 2020. tomatoes.

Photo: Refrigerated trucks in Nigeria © GAIN

Reclaiming Indonesia's Fish for Improved Nutrition

Fish Market in Indonesia © GAIN

After Nigeria, PLAN expanded to Indonesia in 2017. In Indonesia, aquatic foods account for at least half of the nation's animal protein consumption. [5] Indonesia has one of the highest fish supplies in the world at 6 million tons annually, yet 35% of fish in Indonesia is lost or wasted between harvest and markets due to poor transport and storage infrastructure and practices .[6]

Indonesia loses approximately 13 million tonnes of fish annually, equivalent to 300 kg per 7 person each year . I‑PLAN became the bridge between the Ministry of Health and the Ministry of Fisheries to find solutions for fish loss and increase access to fish consumption.

Of PLAN's three‑tier approach, the Innovation Challenge was first launched in Indonesia, attracting over 500 entries. The first prize was accorded to an innovation for an ice substitute called Maslaha Cold Bank. Within six months, Maslaha received over USD 500,000 from a private investor and sold over 14,400 cold banks to fish supply chain actors. Commenting on the Innovation Challenge, Teale Yalch said, “During the second competition in 2019, we really wanted to bridge the gap between supply and demand of fish products, so we called for innovations that helped repurpose fish that would otherwise have been lost or wasted to create desirable fish products for Indonesian consumers.” With this objective as key to its innovation, I‑Fit Fish Cereal, producing nutritious fish‑based cereal, won the 2019 competition. With I‑PLAN's support, I‑Fit Fish cereal's sales grew quickly, increasing by 8,350 boxes from January to July 2020 and generating revenue of IDR 170,600,000. Additionally, when the COVID pandemic hit, the Indonesian Government purchased a large amount of these nutritious breakfast cereals from I‑Fit to distribute to low‑middle income families with challenges in accessing nutritious foods.

I‑PLAN's notable achievements included signing up more than 500 organisations, training over 300 individuals on improved post‑harvest loss practices and technologies, helping over 100 businesses apply improved post‑harvest loss practices and technologies in their businesses and identifying over 500 post‑harvest loss innovations.

After its initial development phase, the I‑PLAN Alliance in Indonesia was re‑named as JP2GI, and now runs independently, comprising more than 600 fish supply chain members across Indonesia. The Ministry of Health and Maritime Affairs in Indonesia signed an agreement in 2019, independent of GAIN and I‑PLAN to promote excellence in Indonesian human capital through increased fish consumption.

Reusable plastic crates to curb the loss of tomatoes in Ethiopia

In 2018, PLAN expanded to Ethiopia with a focus on tomatoes. In Ethiopia, small‑scale farmers were transporting tomatoes over long distances using wooden crates that were often of varying sizes, stacked on top of one another, over long distances and bumpy roads. As a result, many tomatoes were destroyed during transportation.

PLAN identified reusable plastic crates (RPCs) as a potential solution to help prevent damage to the tomatoes during the journey from the farm to the market. Unlike wooden crates, RPCs reduce PHL by eliminating overloading with better stackability nestability, and because they can be cleaned, RPCs can help reduce food safety risks as well. An FAO analysis estimated that using these crates in Ethiopia could eliminate 5‑10 percentage points of loss compared to wooden crates currently being used [1].

PLAN Ethiopia provided 19,000 RPCs to alliance member businesses based on a co‑funding agreement signed with beneficiaries who procured an additional 19,000 RPCs from their funding sources. PLAN Ethiopia also worked with the local agricultural university to create a specialized PHL training curriculum, which was then used to conduct training on improved postharvest technologies and business management for 165 supply chain businesses and 26 respective government employees.

Ensuring nutritious food reaches consumers is a complex challenge

PLAN faced several challenges in achieving its objectives during the five years in Nigeria, Indonesia and Ethiopia. Firstly, financing PHL‑reduction technologies remains challenging for SMEs because banks see innovations as highly risky.

Technology scalability depended on affordability and readiness, necessitating business involvement for successful adoption.

For example, "The tricky thing about reusable plastic crates is you need to find a business model that supports their continual circulation across the supply chain (upstream and downstream both), and you need buy‑in from all actors. We could do this in Ethiopia and Nigeria with a few early adopters," said Yalch. Commercializing and scaling PHL technology innovations will continue to require innovative business models that work in low‑income settings.

Measuring the project's impact on food loss reduction during implementation also proved challenging. It required funding outside of the project implementation phase, for assessing PHL before and after the interventions

The way forward: Coordination and capacity-building across supply chains

Improvements in cold chain storage and logistics, crating and packaging, are key in increasing the shelf life of nutritious foods like tomatoes and fish perishables.

Since the end of the project, PLAN has continued to highlight its several successes. OTACCWA is the leading champion of cold chain technologies in Nigeria and ECOWAS countries. Notable activities at OTACCWA include hosting workshops and capacity‑building training on the cold chain supply of perishable commodities and an annual West Africa Cold Chain Summit and Exhibition (WACCSE), now in its sixth edition.

The I‑PLAN Alliance in Indonesia (re‑named JP2GI) has been run independently and boasts more than 600 members across Indonesia. Over 200 members have applied improved postharvest loss technology and practices to their businesses, with over 20,000 cold chain technology products sold and used by 400 fishermen and 56,000 fish‑based food products sold in the local market.

In March 2022, I‑PLAN, founded by GAIN with the support of the Ministry of Foreign Affairs of the Kingdom of the Netherlands, won the Best Practices Award in Sustaining Urban Food Systems at the Dubai International Award for Best Practices. The experiences of PLAN in Nigeria, Indonesia and Ethiopia highlight the considerable potential for improving supply chain efficiency with greater coordination, technology adoption and capacity‑building across supply chains to reduce the loss of nutritious foods.

………………………………………………..

References

- Arnold, R., ‘Towards zero food waste in Indonesia’s fishing communities,’ IFAD, September 2020, https://www.ifad.org/en/web/latest/-/story/towards-zero-food-waste-in-indonesia-s-fishing-communities

- FAO, ‘The state of world fisheries and aquaculture,’ Food and Agriculture Organization, 2022, pp. 1-266, https://www.fao.org/3/cc0461en/cc0461en.pdf

- GAIN, ‘Driving Innovation and collective action in Indonesia’s fish value chain,’ Global Alliance for Improved Nutrition, 2023, pp. 1-4, https://www.gainhealth.org/sites/default/files/publications/documents/driving-innovation-and-collective-action-in-indonesia-fish-value-chain.pdf

- GAIN, ‘Impact Story 20: Reducing Postharvest Losses in Fresh Fruits and Vegetables in Nigeria,’ Global Alliance for Improved Nutrition, October 2022, pp. 1-2, https://www.gainhealth.org/sites/default/files/publications/documents/20-Impact%20Stories-31Oct22.pdf

- GAIN, ‘Strengthening the business links in Nigeria’s cold chain,’ Global Alliance for Improved Nutrition, 2023, https://www.gainhealth.org/resources/reports-and-publications/strengthening-business-links-nigerias-cold-chain

- Kalmpourtzidou, A., Eilander, A., and Talsma, E., ‘Global vegetable intake and supply compared to recommendations: A systematic review,’ Nutrients, vol. 12, no. 6, 2020, p. 1558, https://doi.org/10.1016/j.worlddev.2014.08.002

- Yalch, T., Lofthouse, J., and Nordhagen, S., ‘Creating alliances and fostering innovations to reduce post-harvest loss of nutritious food,' Global Alliance for Improved Nutrition, no. 9, August 2020, pp. 1-20, https://www.gainhealth.org/sites/default/files/publications/documents/gain-working-paper-series-9-creating-alliances-and-fostering-innovations-to-reduce-post-harvest-loss-of-nutritious-food.pdf

- [1] Rapusas RS, Rolle RS. Management of reusable plastic crates in fresh produce supply chain [Internet]. Rome: Food and Agriculture Organization of the United Nations; 2009. Available from: http://www.fao.org/3/i0930e/i0930e00.pdf