This case study highlights Askah Nyakwara, a food waste champion and the company's founder Nyangarora Banana Processors (NBP) in Kisii, Western Kenya. The banana industry is characterised by high food loss from roots, stems, bark, leaves, flowers, rejected or overripe fruits, and their peels. Through their innovative efforts, NBP has reduced post‑harvest losses from 40% to 15% in their operations over 10 years.

Access the downloadable version of this case study and the complete compendium.

Key messages

- Worldwide, about 114.08 million metric tons of banana waste‑loss (equivalent to 22 million passenger vehicles) are produced, leading to environmental problems such as the excessive emission of greenhouse gases.

- Bananas are the second most‑produced fruit after citrus and the fourth most important food crop after rice, wheat and corn.

- Through processing and value addition, bananas can be upcycled into crisps and flour with nourishing qualities, while the waste by‑product can be used as natural fibres.

- Increasingly, budding Small and Medium Enterprises (SMEs) like Nyangorora Banana Processors in sub‑Saharan Africa are repurposing indigenous foods to boost incomes,nourish communities, and cultivate sustainable livelihoods.

Bananas are the fourth‑most important food crop after rice, wheat and corn [1]and provide essential micronutrients for human growth and development. Banana farming in central andwestern Kenya is a source of livelihood for small‑scale farmers and an essential component [2] of the country's food security and agricultural sector.

The banana processing industry is characterised by high food loss and waste loss from roots, stems, bark, leaves, flowers, rejected or overripe fruits, and their peels. A single banana plant produces waste of up to 80% of its total plant mass. [3]

In 2006, a youth group providing extension training for the local community on modern farming methods in the western part of Kenya, in Kisii, was launched. Almost two decades later, the project morphed into Nyangorora Banana Processors (NBP), a company that Askah Nyakwara founded. NBP unlocks the potential of banana waste, such as stems, peels and leaves often discarded during banana processing. Through their innovative efforts, since 2013, NBP has reduced post‑harvest losses from 40% to 15% (currently) in their operations.

Milestones of NBP

- Nyangorora Banana Processors was established in 2013 and is currently incubated at the Kenya Industrial Research Institute (KIRDI) in Kisii, Kenya.

- In 2016, Askah Nyakwara was recognised as the 'Smart Entrepreneur Of The Year' in Kenya, during an entrepreneurship summit organised by CPF Financial Services.

- NBP received equipment for banana crisps production from USAID worth USD 10,000

- NBP has an estimated sales turnover of $10,000 every month with a production volume of 3,000 kilogrammes of banana crisps.

- Through GAIN and the SUN Business Network (SBN) Kenya they have established market linkages and benefited from benchmarking opportunities with other companies for foods that are nutritious and suitable for consumption by children.

- Through the support of Switch Africa Green, they were able to acquire solar dryers that has increased their processing productivity.

- In 2023 NBP also became ISO certified. The company is also certified by KEBS (Under Ministry of Industrialization, Trade & Enterprise Development in Kenya that develops food standards, and rules on quality assurance and testing) and NEMA (Under Ministry of Environment & Forestry in Kenya that oversees environmental safety issues and conducts environmental impact assessments).

Photo: Askah Nyakwara being awarded the entrepreneur award in 2016 by CPF Financial Services

Askah Nyakwara, the food waste champion from Kisii

Meet Askah Nyakwara, a 40‑year‑old food waste champion who lives in Nyangorora village in Kisii, Kenya, with her husband and three children. Askah's journey as an entrepreneur in exploring value‑adding opportunities to extend the shelf life of bananas and reduce food loss and waste (FLW) began three decades ago when she was just a little girl. Growing up, Askah assisted her mother in selling bananas and witnessed how most small‑scale farmers like her mother hardly made a profit after waiting for a year for an entire banana bunch to mature.

“It was always the middlemen making a profit and not my mother who had toiled on the farm as it takes 9 to 12 months for a banana bunch to mature. The irony was that after all that hard work and wait, a full banana bunch weighing about 7‑12 kilos was being sold for less than 2 USD. This was not enough money to pay for my school fees and other needs in the family,” said Askah Nyakwara.

“We started by making the banana crisps in my mother's kitchen.[4] Later, we moved to KIRDI to expand our operations. To streamline our processes and minimise banana waste, we repurposed the leftovers into flour and launched a new product line of doughnuts and porridge flour, now a popular healthier breakfast alternative for babies and school‑going children,” says Askah Nyakwara, Founder of Nyangorora Banana Processors.

According to Lamec Mogire, KIRDI Center manager, “It has been a win‑win situation for NBP and the community as the SME we currently house at KIRDI has created employment and is helping to improve the community's nutrition through the fortified banana flour high in banana flour high in potassium, vitamin C and phytonutrients.”

NBP purchases bananas from over 40 collection centres located in Kisii and Nyamira, in Western Kenya, representing over 5,000 small‑scale banana farmers. The extension farming training that she received from Kenya Agriculture and Livestock Research Organization (KALRO) between 2004‑2008 enabled her to identify the best crop variety for various products, the Ngombe Grade One banana variety for the banana crisps, Giant Cavendish, William and Grand Nine variety for the wine and juice

production and Uganda Green for making the porridge flour. Nyakwara added, “In my community, bananas are readily available and cheap, so mothers who are underprivileged in certain ways prefer to feed their children mashed bananas as it is very filling. Here I found many mothers were eager to and looking for options to diversify their children's diets, but could ill afford it.” says Aksah.

Processing of raw bananas into next stage product variants

As a response to her community's nutritional challenges, Nyakwara launched a unique banana porridge mix. The porridge mix from NPB is nutritious and gluten‑free and is increasingly preferred by mothers as it includes sorghum, pumpkin seed and finger millet blend, and is much‑liked by children as well.

Running a Circular Business Model

A banana stems only fruits once in the year, and is often left to rot in the field or burned. Banana stems, leaves and overripe bananas left to rot on farms after harvesting create breeding grounds for pests, diseases and emit methaneous odours. Askah felt that it was time for her community to maximise the potential of the banana tree, which was locally grown in her community. She has since been able to implement a circular business model in her operations at NBP.

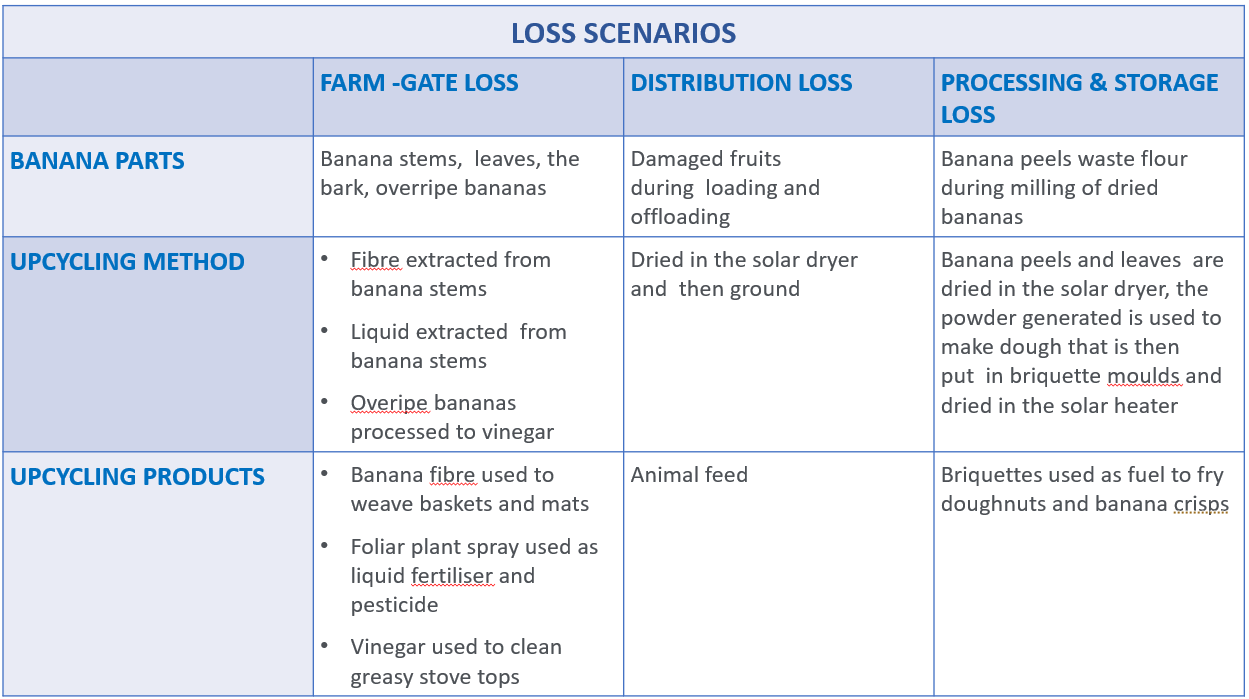

This table depicts the ‘circular business model’ employed at Nyangorora Banana Processors.

Technology transfer and partnerships

In 2008, she participated in a one‑month training residency at Texfad in Kampala, Uganda. Texad offers non‑formal skills training programme to women and youth on how to convert banana stems to high quality sustainable textile products.[5]Through her apprenticeship with Kimani Muturi the founder of Texfad, Nyakwara learnt how to extract fibre from banana stems and how to upscale banana fibre extraction for premium textile making.[6]

“Waste is money. A banana stem that would have been burned down or left rotting in the field is now generating about $50 in return after we extract the fibre and weave it into a mat or rug,” said Askah.

NBP has been able to create a difference in the community. The ISO‑certified company currently employs 16 young people. Ms. Nyakwara has also created awareness in her community on the importance of reducing banana waste and has trained women and youth to create banana fibre from the banana stems. As a result, hundreds of women and youth have been equipped with the skills on how to transform readily‑available banana stems to fibre.

“We buy the fibre and finished products from our trainees and as a result the guaranteed

sales of their products motivates them to continue upscaling the waste stems readily

available in their farms. This has contributed to a cleaner environment and also created

employment opportunities for the many women and youth in our network.”

Over 50 students from Kisii National Polytechnic have completed their apprenticeship at NBP since 2013, the students have gained skills on reducing food waste by extending the shelf life of fruits such as mangoes, tomatoes and traditional vegetables through drying and packaging.

With support from the Scaling up Nutrition Business Network (SBN) Kenya, NBP has been able to access peer‑to‑peer learning opportunities to benchmark its products such as the baby porridge. Co‑convened by GAIN and World Food Programme, SBN promotes a multisectoral and multi‑stakeholder approach to tackling malnutrition by providing technical support and facilitating peer‑to‑peer learning through regional and country chapters.

Briquettes made from waste banana peels and leaves

Through the support of Switch Africa Green, a programme developed and funded by the European Union and implemented by the United Nations Environment Programme (UNEP) NBP installed solar dryers in their factory. The dryers are not only used for drying bananas but also used by other entrepreneurs to dry fruits and vegetables so as to reduce the post harvest losses of horticulture in the area. They also gained skills on how to be more resource efficient and how to embrace environmentally friendly practices. According to the Global Forest Watch, In 2010, Kisii had 46.6 kha of natural forest, extending over 38% of its land 7 area. In 2022, it lost 33 ha of natural forest, equivalent to 24.0 kt of CO₂ emissions.

Nyakwara drew attention to the ongoing deforestation in her community, “Charcoal burning and the use of firewood in the Kisii area has resulted in massive deforestation. We have replaced the use of charcoal and firewood in our banana crisps and doughnut fryers and instead use our energy efficient briquettes made from banana peels and leaves, as a result we have been able to make lots of savings on energy costs.” The briquettes are typically drier than firewood which helps them burn more cleanly and efficiently, they are more energy dense and are able to maintain consistent temperature for a long time burning slower than firewood and charcoal.

Market access and challenges in distribution

Processing banana waste on farms can be challenging due to various factors. Banana fibres had traditionally been extracted from the banana stem using manual processes involving scrapping the banana sheath until the fibres were unearthed. This banana waste upcycling process is labour‑intensive and not viable for commercial production. The special equipment required to process the banana stem is expensive, pushing up the production costs for banana fibre.

NBP has also faced a challenge in distributing its products. In the past, distributors have made away with their products and sales proceeds, resulting in major losses. Also, major retail stores and supermarkets offer unfavourable payment terms (30‑90‑day), negatively impacting their cash flow.

To guarantee profitable sales, Askah distributes her finished textile products to high end markets locally and internationally, where she sells her products to customers who prefer crafted, eco‑friendly rugs, mats and baskets. A shopping basket made from banana fibre retails at 50‑70 USD.

The company has embraced e‑commerce, they use WhatsApp and Facebook to advertise, local delivery Apps to deliver their product to their customers across Kenya and mobile money applications to receive and track payments.

Looking ahead

NBP has expansion plans. Due to the rise of more conscious consumers pushing the demand for eco‑friendly products such as mats, NBP aspires to raise additional capital to expand its operations. “We recognise that it is time for us to be more independent and transition from our current incubation hub, KIRDI, to our facility. There is still a big gap in mentoring entrepreneurs, and we would like to extend the same support offered to us at KIRDI and help other budding entrepreneurs grow,” added Askah.

In the near future, NBP plans to launch a training institute and incubation hub that will train women and youth in Kisii county on banana value addition and how to reduce FLW in the banana value chain.

In conclusion, Nyangorora Banana Processors (NBP) is a game‑changing initiative that has unlocked the potential of reducing banana waste in Kisii, Kenya. Their approach is not only environmentally friendly but also economically viable. As such, it serves as a model for other entrepreneurs working in high‑waste‑producing food businesses to follow.

References

- Acevedo, S. et al., ‘Recovery of banana waste-loss from production and processing: A contribution to a circular economy’, Molecules, Vol. 26, no. 17, 2021, p. 5282. https://doi.org/10.3390%2Fmolecules26175282

- AN, ‘Kenyan entrepreneur turns profit in banana snack business’, Africanews, 2016. https://www.africanews.com/2016/05/04/kenyan-entrepreneur-turns-profit-in-banana-snack-business/, (accessed 27 October 2023).

- Castillo, M., de Guzman, M., and Aberilla Mikhail, J., ‘Environmental sustainability assessment of banana waste utilization into food packaging and liquid fertilizer’, Sustainable Production and Consumption, Vol. 37, 2023, pp. 356–368. https://doi.org/10.1016/j.spc.2023.03.012

- CropTrust, ‘Banana / plantain’, Crop Trust - Securing our food, forever, 2023. https://www.croptrust.org/pgrfa-hub/crops-countries-and-genebanks/crops/banana-/-plantain/, (accessed 27 October 2023).

- GFW, ‘Kisii, Kenya deforestation rates & statistics: GFW’, Global Forest Watch, 2023. https://www.globalforestwatch.org/dashboards/country/KEN/16/?category=land-cover&location=WyJjb3VudHJ5IiwiS0VOIiwiMTYiXQ%3D%3D, (accessed 27 October 2023).

- Ibrahim, A., ‘Banana waste upcycling boosts Uganda’s circular economy’, World Economic Forum, May 2023. https://www.weforum.org/agenda/2023/05/how-banana-waste-is-transforming-uganda-s-circular-economy/, (accessed 27 October 2023).

- IICA, ‘Bananas: A key crop for food security that is under threat’, Inter-American institute for cooperation on agriculture, https://iica.int/en/press/news/bananas-key-crop-food-security-under-threat, 2023. (accessed 27 October 2023).

- Ssenjala, F., ‘Services we offer’, TexFad, 2023. https://texfad.co.ug/services.php, (accessed 27 October 2023).